NUMERICAL MODELING AND PROCESS SIMULATION OF COUPLED ELECTROMAGNETIC, THERMAL AND STRUCTURAL MECHANICAL EFFECTS

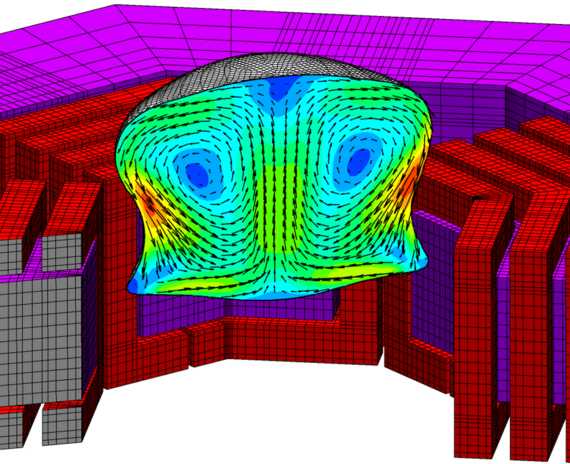

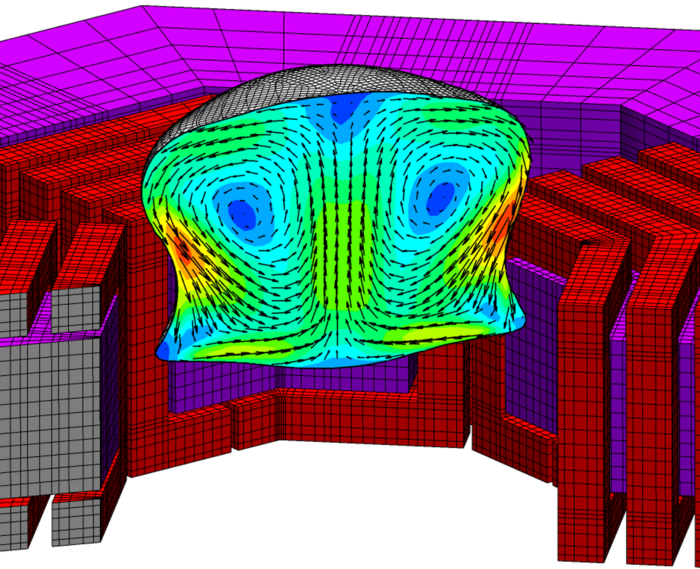

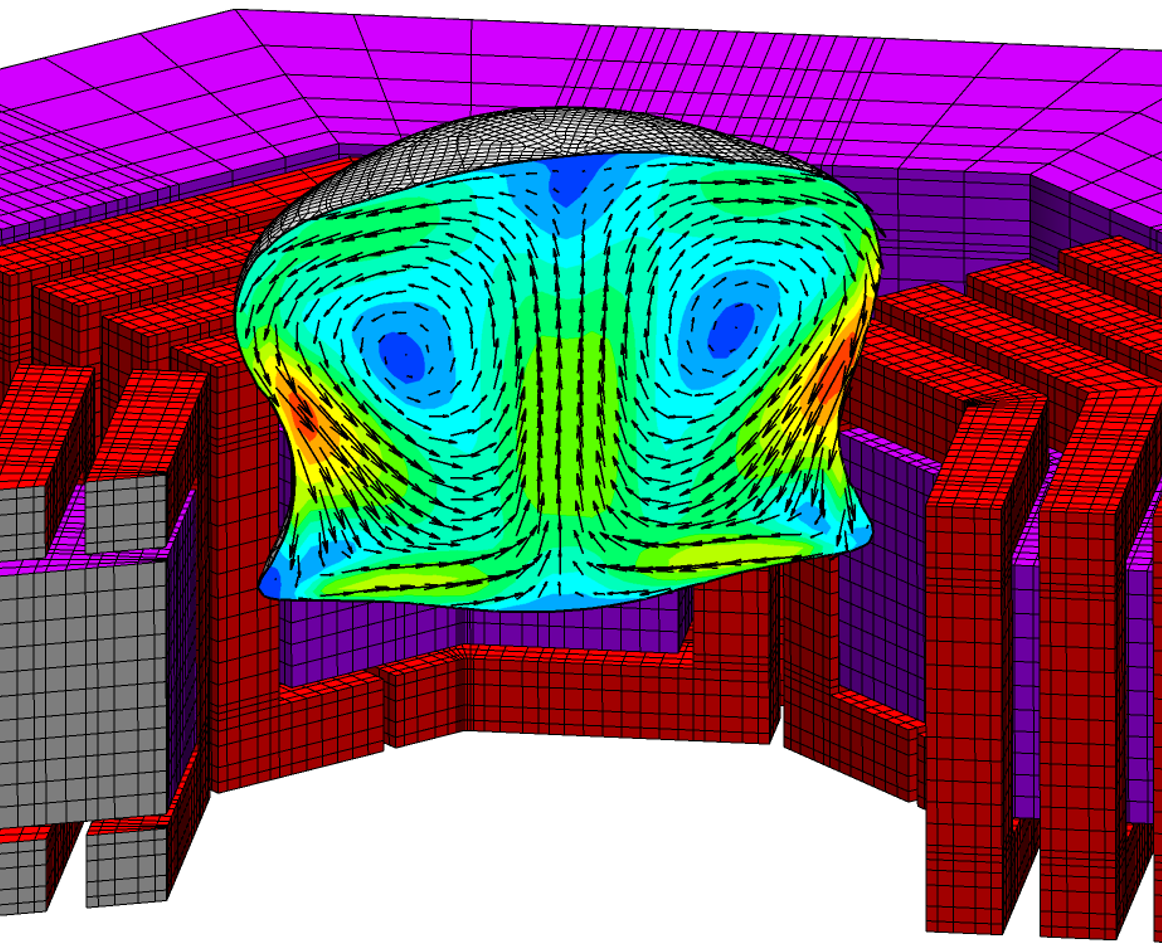

Numerical modeling and process simulation is one way to describe and investigate complex electromagnetic, thermal and structural mechanical processes. In the Finite Element Method (FEM), which is the basis of the commercial software package ANSYS®, the system under consideration is broken down into a number of finite elements. The physical processes are described by differential equations and solved numerically under consideration of the boundary conditions. The advantage of geometrically simple models, which can mostly be described in two dimensions, is the short calculation time. For a complex problem, however, a three-dimensional calculation must often be considered at the expense of the running time. In the case of electromagnetic-thermally coupled systems, transient heating and cooling processes can be the focus of attention in addition to a static consideration. Temperature-dependent material properties are taken into account by a continuous coupling of both calculation steps.Furthermore, besides the heat conduction in the workpiece, the radiation losses as well as the convection can be considered numerically.

Structural mechanical effects can also be taken into account. In this case, for example, the estimation of thermal stress due to material expansion with increasing temperature can be in the foreground. The numerical simulation mentioned above is used in many different areas nowadays. For example, the process simulation of "strip heating in a transverse magnetic field" or "surface hardening of complex geometries" represents only a fraction of the possible electromagnetic, thermal and structural-mechanical calculations.

At the end of a process simulation of this kind, the results are generally verified in a test facility. Good matches allow a numerical optimization of the essential geometrical parameters. In combination with automatic optimization algorithms, for example by using genetic algorithms, a fast and cost-effective parameter optimization can be carried out.

With lower manufacturing costs and shorter development times, the advantage of numerical simulation over traditional product development is obvious.